High speed, hight stability, high precision, fully automatic tension control system, intelligent PLC control system, easy operation, CE certificated by SGS, the slitting rewinding machine is an idea equipment for slitting wide jumbo roll paper into small and various rolls in different widths.

|

|

*1. Using man-machine interface control system, operating at a glance. Paper Rack s Material: 50# Steel Clutch device: Magnetic Braker and control |

|

|

*2. SIEMENCE PLC 1) Automatic Shutdown 2) Automatic Meter Calculation 3) Automatic Web Correction System 4) PLC control, Set through the Touch Screen

|

|

|

*3. The machine uses three servo motor with synchronous control system. |

|

|

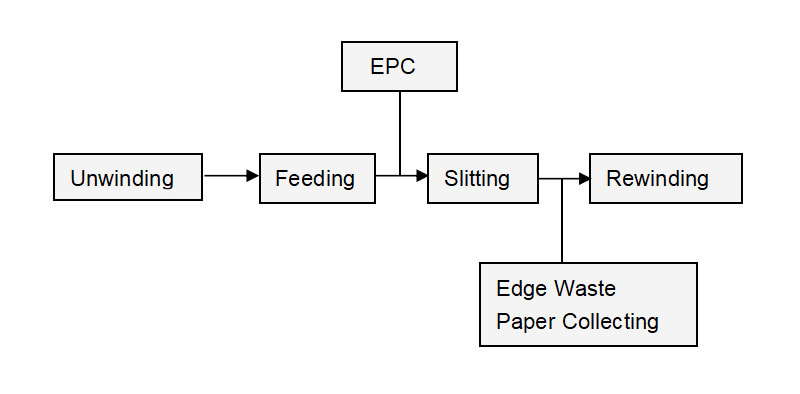

*4. EPC Web Guiding System by photoelectric sensor |

|

|

*5. Fully Automatic Tension Control System When the paper goes through sensor, it gives feedback to the PLC control system automatically to increase brake load, which controls the paper tension automatically by increasing or reducing the tension. |

|

|

*6. High precision slitting knife system According to client’s demands, we will arrange all widths in one shaft with easy to operation and high accuracy with SKD material. |

|

|

*7. Unwinding System With standard configuration, we are using air shaft. Shaftless could be optional, which is more convenient to operate and change the roll paper. |

|

|

*8. Rewinding System 1) Use A and B air shafts to rewind the finished roll, unloading the finished rolls automatically, in general we use 3” air shafts, however the size could be customized. 2) Each air shaft is controlled by one motor |

|

|

*9. Automatic Stripping Trimming System |

|

Model |

1300 |

1600 |

1800 |

Customization Available |

|

|

Mother Roll Width |

Max width 1300 mm |

Max width 1600 mm |

Max width 1800 mm |

||

|

Mother Roll Diameter |

Max.Ф1400mm |

||||

|

Mother Roll Paper Core Diameter |

3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

||||

|

Mother Roll Weight |

Max. 1200kg (Air Shaft) |

||||

|

Roll Paper Weight Range |

15-500g/m2 |

||||

|

Finished Roll Width |

Min. width 30mm(depends on paper) |

||||

|

Finished Roll Diameter |

Max. Ф1000mm |

||||

|

Production Speed |

Max 0-500m/min (depends on different paper quality) |

||||

|

Cutting Accuracy |

±0.2mm |

||||

|

Slitting Numbers |

According to the clients’ demand (normal 15 Sets Round Knives) |

||||

|

Main Power Supply |

380V /50HZ |

||||

|

Machine Dimension |

4500*2800*1950mm |

4500*3200*1950mm |

4500*3800*1950mm |

||

|

Machine Weight |

4500kg |

5200KGS |

6000KGS |

||

|

Power |

26KW |

26KW |

38KW |

||

|

Air Consumption |

200NL/min |

||||

|

Air Pressure |

6-8 bar |

||||

|

Edge Cutting |

5~10mm*2 |

||||

It’s widely used in printing, packaging and paper products industries, such as kraft paper, news paper, silicone paper, thermal paper, fluting paper, sublimation paper, glassine paper, coated paper, recycled paper, paper cardborad, A4 copy paper, laminated paper, linear paper, wax coated paper, oil proof paper, tipping paper, cigarette filter paper, tobacco paper, medical paper, water proof paper, plastic film, foil paper, glossy paper, sticker paper, self adhesive paper, duplex paper, non woven fabric and so.

Case-1: Paper Cups And Paper Bowls And Paper Lid, Wrapping Paper Project

The model paper slitting rewinding machines are widely used in paper disposables packaging manufacturers for pe coated paper, silicon coated oil proof paper, such as paper cup, paper bowl, paper lid, paper plate, rice and burger wrapping paper etc. Usually the manufacturers purchase one wide jumbo roll paper to slit it into different and narrow widths to get what they need, such paper bottom for paper cup, paper bowl, paper strips for paper lid and so on.

Case-2: Paper Bags Project

Generally the manufacturers adopt the kraft paper and coated grease proof paper to manufacture different kinds of paper bag by roll paper feeding paper bag bottom machine and roll paper square bottom paper bag machie, such as leisure food bags, fenestration bread bags, dried fruit bags and so on environmentally friendly paper bags. The slitting machine rewinding machine can cut these types of jumbo roll paper into customized paper in different widths, such as paper handle etc.

Case-3: Paper Tube & Paper Can Project

Paper tube is an indispensable tool in the paper product industry. The machine that produces paper tube also needs to input small paper rolls of different widths. These inputting small paper rolls width depend on the how much diameter paper tube you want to make. Therefore, we must cut the paper jumbo roll into small rolls of different widths to meet the paper tube production requirements.

Some materials, especially in the paper industry, are produced in large formats. To use and sell as end products, they need to be converted into smaller rolls.

This process for final production is called slitting. This cuts the main kraft label roll into your product’s needs and specific roll widths and sizes.

A slitter is the same as a slitting machine. Other names for the same cutting and slitting machine include slitter rewinder. The terms can be used interchangeably.

There are three common styles: Razor slitting, score slitting, and shear slitting. They have various complexities, set-ups, and uses.

Razor slitting uses a simple single razor blade set-up. The razor could be stationary above the roll or cut along a grooved roll.

This is commonly used for light and smooth materials like thin plastic films.

Score slitting is also known as crush slitting. It is the first-ever form of cutting used by slitter machines. The process “crushes” the material with an anvil to cut it into separate pieces. It uses a dull edge to make the scores on the material.

This is commonly used for adhesives as it creates dry edges and foams.

Shear slitting uses two rotary blades to cut material. It replicates the way a pair of scissors cuts through the material. The blades are positioned precisely and they stay sharp for a long time.

This is commonly used for various materials including paper. But, it is the most ideal for heavier materials like films, sheets, foils, and laminates.

The thermal paper slitter rewinder is a shear slitting machine. It is used for POS, ATM, cash register, NCR, ECG, plotter, and other paper rolls.

Paper Slitting Rewinding Machine as an important part of papermaking machinery, its market trend is affected by the overall development of the global and Chinese pap...

Adjusting the gap and angle of the blade or disc knife of the Paper Roll Slitting Rewinding Machine is a key step to ensure the quality of slitting and rewinding. He...

The Paper Slitting Rewinding Machine is a mechanical equipment commonly used for processing paper, film and other roll materials. It can cut large rolls of materials...

1. The machine cannot startCheck the power supply: confirm whether the power plug is firmly inserted into the socket and whether the power cord is damaged.Check the ...

GET A QUOTE