|

*1. Using man-machine interface control system, operating at a glance. Paper Rack s Material: 50# Steel Clutch device: Magnetic Braker and control |

|

*2. SIEMENCE PLC 1) Automatic Shutdown 2) Automatic Meter Calculation 3) Automatic Web Correction System 4) PLC control, Set through the Touch Screen |

|

*3. The machine uses four servo motor with synchronous control system. Total four sets of servo motors are installed in the machine. Unwinding unit tension is independently controlled by the servo motor. The two rewinding shafts are also driven by two independent servo motors which ensure better rewinding tension controls and reach better rewinding rolls quality. |

|

*4. EPC Web Guiding System moving by Servo Motor The web guide system automatically detects the web edge and adjusts its position, which can improve the slitting accuracy. |

|

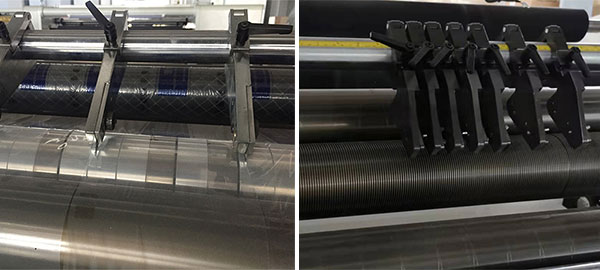

*6. High precision slitting knife system The machine has two types of slitting units, razor knives, and circle knives for various material rolls. They are optional. You also can have both in one machine. Slitting knife shafts can be taken out of the machine. Due to making small width rolls, the model slitting machine has many knives. So this type of knife shaft can be easily adjusted and changed knives. |

|

*7. Unwinding System and Automatic Tension Control It adopts pneumatic shaftless chucks unwinder system with servo motor. The automatci tension is controlled automatically according to the diameter of material. |

|

*8. Rewinding System 1) Use A and B air shafts to rewind the finished roll, unloading the finished rolls automatically, in general we use pneumatic friction rewinding shaft, which has better rewinding tension control performance. 2) Each air shaft is controlled by one motor 3) The unloading system has the pusher device to unload the finished material rolls to the turret. It is easy to operate the machine by only one person. |

|

Model |

1300 |

1600 |

1800 |

Customization Available |

|

|

Mother Roll Width |

Max width 1300 mm |

Max width 1600 mm |

Max width 1800 mm |

||

|

Mother Roll Diameter |

Max.Ф800mm |

||||

|

Mother Roll Paper Core Diameter |

3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

||||

|

Mother Roll Weight |

Max. 1200kg (Air Shaft) |

||||

|

Roll Paper Weight Range |

10-300g/m2 |

||||

|

Finished Roll Width |

Min. width 30mm(depends on paper) |

||||

|

Finished Roll Diameter |

Max. Ф600mm |

||||

|

Production Speed |

Max 0-600m/min (depends on different paper quality) |

||||

|

Cutting Accuracy |

±0.2mm |

||||

|

Slitting Numbers |

According to the clients’ demand |

||||

|

Main Power Supply |

380V /50HZ |

||||

|

Machine Dimension |

4200*2600*1650mm |

4200*2900*1650mm |

4200*3400*1650mm |

||

|

Machine Weight |

3700KG |

4200KG |

4800KG |

||

|

Power |

30KW |

30KW |

30KW |

||

|

Air Consumption |

200NL/min |

||||

This slitter rewinder machine is dedicated to cut flexible packaging material from wide roll materials to narrow ones. All the end customers who have rotogravure printing machine and the solvent-less laminating machine in the plastic packaging material must need this kind of machines. It has perfect performance of slitting and rewinding laminated foil, plastic film(BOPP, OPP, PET, PE, PVC), paper roll materials, label sticker paper, and so on.

Case-1: Bottle Water And Beverage Label Stock Rolls

Many consumer products require film labels, such as bottled water and various beverages. The complete production of film labels requires film blowing machines, printing machines, laminating machines, slitting machines, and the other equipments. The film label manufacturer needs to slit the printed film roll materials into the different widths which are required by the different customers.

Case-2: Self Adhesive Paper Label Stock Rolls, Sticker Label Rolls

Self-adhesive labels are widely used in our lives, such as red wine labels, supermarket price labels, skincare labels, and so on. The width of the self-adhesive coating machine usually exceeds 900mm. The manufacturer of the self-adhesive has to cut large rolls into small rolls in different widths because the width of the die-cutting machine and printing machine for self-adhesive labels doesn’t exceed 500mm.

Case-3: Laminated Film Rolls For Making Food And Medical Pouch

In order to improve the sealing and preservation effect, many food and medicine packaging pouches are using the composite materials, such as aluminum foil and film composite materials, and paper and film composite materials. The performance of composite materials will be better. However, composite materials usually have uneven thicknesses. Therefore, the manufacturers need to use the slip rings friction shaft slitting machine to cut the roll raw materials of lexible packaging.

Slitting machine is a kind of wide roll material longitudinal slitting equipment, slitting machine structure: by the uncoiling (release roll), lead material position...

Some common problems may occur during the rewinding process of the Rewinding Machine. Here are some common paper roll problems and how to deal with them:1. The probl...

1. Material adaptability:Surface winding slitting machines have excellent material adaptability and can adapt to many types of materials, while traditional machines ...

They say you can’t have your cake and eat it too, but this model may refresh your knowledge!1. Improve production efficiency: The paper slitting and rewinding machin...

GET A QUOTE