The roll paper sheet cutting machine is widely used for wrapping paper packaging for sandwich, burger, rice, fruit, paper bag sheets, files PVC covers, medical film, paper sheets, plastic film, non woven fabric material, aluminium foil, A4/A3 copy paper, self adhesive paper, sticker paper, wax coated paper, silicon coated paper, IML sheets for packaging materials and so on. The machine includes automatic stacking system, automatic counting system, and automatic delivery system.

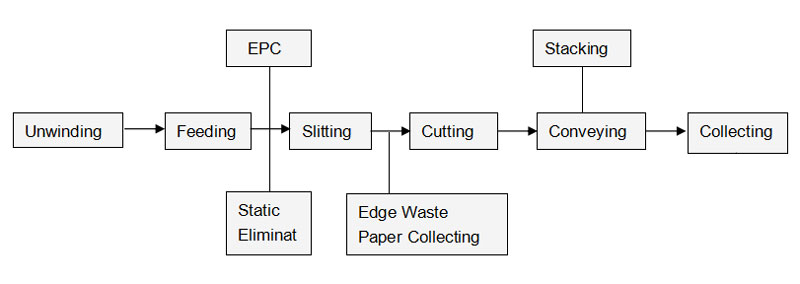

Wnwinding→ Cutting → Conveying → Collecting

|

*1. Using man-machine interface control system, operating at a glance. Paper Racks Material: steel plate and casting steel structure, wallboard 16mm, which ensures that the machine keeps running stably. |

|

*2. PANASONIC PLC 1) Automatic Shutdown 2) Automatic Meter Calculation 3) Automatic Web Correction System 4) PLC control, Set through the Touch Screen |

|

*3. Unwinding System With standard configuration, we are using air shaft. Shaftless could be optional, which is more convenient to operate and change the roll paper. We could feed multiple rolls – 2 rolls, 4 rolls |

|

*4. Fully Automatic Tension Control System When the paper goes through a sensor, it gives feedback to the PLC control system automatically to increase brake load, which controls the paper tension automatically by increasing or reducing the tension. |

|

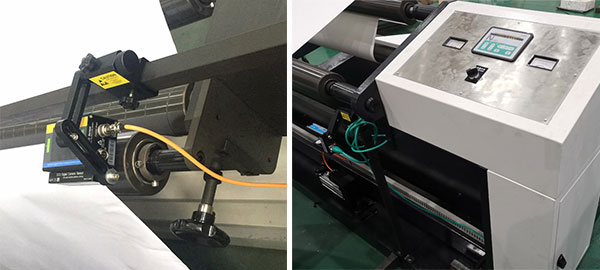

*5. EPC Web Guiding System by a photoelectric sensor |

|

*6. Oscillating Bar Device The oscillating bar device can control the paper tension stably. And the machine used aluminum rollers and PU rollers: The PU rollers have the characteristic of high abrasive resistance, which can insure machine feeding precision. All rollers have undergone concentricity testing and dynamic balance treatment to ensure the stable conveyance of materials during the operation of the machine. |

|

*7. Feeding Unit The machine adopts one servo motor and two synchronous motors to feed the roll paper stably. And it makes the machine working with a high level cutting precision(0.2mm error range). |

|

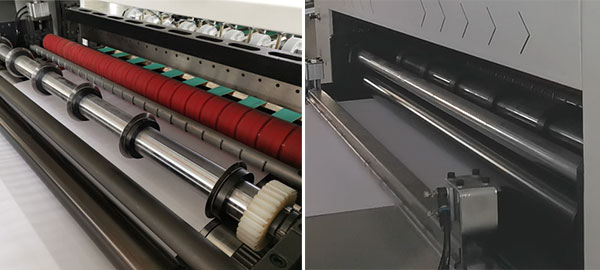

*8. Slitting Unit Slitting Precision: ±0.2mm The machine includes different sets of round slitting knives according to the different machine widths, you could adjust the knives position by manual. Upper slitting knife is round self-locking knife. It can be moved up down, left and right by hand wheel easily. Lower knife connects with bearing drive which could be operated easily.

|

|

*9. Static Bar Static Elimination: The machine has statics bar to eliminate the statics influence.

|

|

*9. Automatic Stripping Trimming System |

|

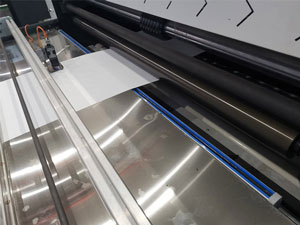

*10. Cutting Unit It adopts the heavy casting structure and guillotine knife, and you can adjust the position by manual. |

|

*11. Conveyor Belt with Automatic Counting and Stacking System Automatic Counting: The machine will automatically count the quantity of the cutting sheets and stop when it reaches the quantity which is set in the PLC. Non stop: When the operator collects the finished cutting sheets, the machine doesn’t stop and continue to cut paper sheets. Vibrate Board For Collection: it could ensure that the stacking paper will be collected neatly. |

|

Model |

1100 |

1400 |

1600 |

Customization Available |

||

|

Feeding Roll |

One Roll/Two Rolls/Four Rolls |

|||||

|

Mother Roll Width |

1100 mm |

1400mm |

1600mm |

|||

|

Mother Roll Diameter |

Max.Ф1400mm (Air Shaft) |

|||||

|

Paper Core Diameter |

3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

|||||

|

Mother Roll Weight |

Max. 1400kg (Air Shaft) |

|||||

|

Roll Paper Weight |

18-100g/m2 |

|||||

|

Cutting Length |

100-600mm |

|||||

|

Pile Stack Height |

Max 500mm |

|||||

|

Cutting Speed |

30-200times/min |

|||||

|

Cutting Accuracy |

±0.2mm |

|||||

|

Machine Dimension |

7500×2300×1800mm |

7500×2600×1800mm |

7500×2900×1800mm |

|||

|

Machine Weight |

4000KGS |

4500KGS |

5300KGS |

|||

|

Power |

12KW |

14KW |

18KW |

|||

Paper Slitting Rewinding Machine as an important part of papermaking machinery, its market trend is affected by the overall development of the global and Chinese pap...

Adjusting the gap and angle of the blade or disc knife of the Paper Roll Slitting Rewinding Machine is a key step to ensure the quality of slitting and rewinding. He...

The Paper Slitting Rewinding Machine is a mechanical equipment commonly used for processing paper, film and other roll materials. It can cut large rolls of materials...

1. The machine cannot startCheck the power supply: confirm whether the power plug is firmly inserted into the socket and whether the power cord is damaged.Check the ...

GET A QUOTE