High speed, hight stability, high precision, fully automatic tension control system, intelligent PLC control system, easy operation, CE certificated by SGS, the slitting rewinding machine is an idea equipment for slitting wide jumbo roll paper into small and various rolls in different widths.

|

Name |

Normal |

|

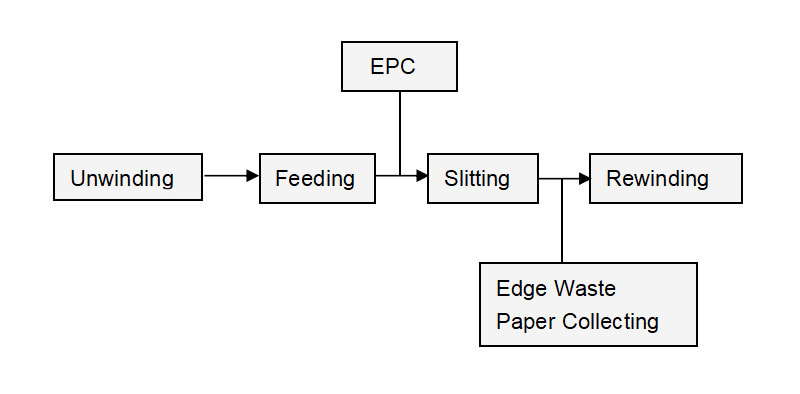

PLC |

Siemens, Germany |

|

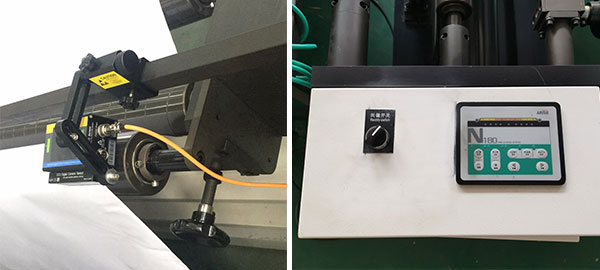

EPC(web guider) |

Arise, China |

|

Motor |

Duochuan, China |

|

Inverter |

Farwide, China |

|

Bearing |

HBR, China |

|

Unwinding part |

Air shaft |

|

*1. Using man-machine interface control system, operating at a glance. Paper Rack s Material: 50# Steel to make sure that the machine can avoid shaking when the machine runs stably at high speed and it can improve the slitting accuracy. Clutch device: Magnetic Braker and control |

|

*2. SIEMENCE PLC – Intelligent System 1) Automatic Shutdown 2) Automatic Meter Calculation 3) Automatic Web Correction System 4) PLC control, Set through the Touch Screen 5) Automatic Emergency Stop |

|

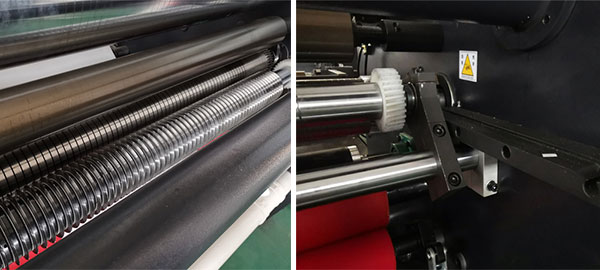

*3. The machine uses three servo motors with synchronous control systems which are used for transmission of roll paper materials and the two rewinding rolls after high speed slitting. |

|

*4. EPC Web Guiding System by a photoelectric sensor which can identify the paper edge and adjust the paper position automatically |

|

*5. Fully Automatic Tension Control System When the paper goes through the sensor, it gives feedback to the PLC control system automatically to increase brake load, which controls the paper tension automatically by increasing or reducing the tension. |

|

*6. High precision slitting knife system and Knife Guide According to client’s demands, we will arrange all widths in one shaft with easy to operation and high accuracy with SKD material. The rewinding shaft are rotated and it will be much easy to unload the finishing rolls by manual.

|

|

*7. Unwinding System With standard configuration, we are using air shaft. Unwinding structure uses the hydraulic system, which can load the roll materials more easily with less labor. Shaftless could be optional, which is more convenient to operate and change and upload the roll paper. |

|

*8. Rewinding System 1) It adopts the central surface rewinding that can control the tension perfectly. 2) Use A and B air shafts to rewind the finished roll, unloading the finished rolls automatically, in general we use 3” air shafts, however the size could be customized. 3) Each air shaft is controlled by one motor 4) Automatic pneumatic unloading method is adopted on the two rewinding shafts.

|

|

*9. Automatic Stripping Trimming System The slitter edge will be gone out automatically by blower. |

|

Model |

800 |

1100 |

1300 |

||

|

Mother Roll Width |

Max width 800 mm |

Max width 1000 mm |

Max width 1300 mm |

||

|

Mother Roll Diameter |

Max.Ф1400mm |

||||

|

Mother Roll Paper Core Diameter |

3”(76.2mm)or 6”(152.4mm) or according to the clients’ demand |

||||

|

Mother Roll Weight |

Max. 1200kg (Air Shaft) |

||||

|

Roll Paper Weight Range |

20-400g/m2 |

||||

|

Finished Roll Width |

Min. width 5mm |

Min. width 7mm |

Min. width 7mm |

||

|

Finished Roll Diameter |

Max. Ф600mm |

||||

|

Production Speed |

Max 0-400m/min (depends on different paper quality) |

||||

|

Cutting Accuracy |

±0.2mm |

||||

|

Slitting Numbers |

According to the clients’ demand (normal 15 Sets Round Knives) |

||||

|

Main Power Supply |

380V /50HZ |

||||

|

Machine Dimension |

3500*2300*1650mm |

3500*2800*1650mm |

3500*3200*1650mm |

||

|

Machine Weight |

3000kg |

3700kg |

4300kg |

||

|

Power |

18KW |

18kw |

21kw |

||

|

Air Consumption |

200NL/min |

||||

|

Air Pressure |

6-8 bar |

||||

|

Edge Cutting |

5~10mm*2 |

||||

Paper Slitting Rewinding Machine as an important part of papermaking machinery, its market trend is affected by the overall development of the global and Chinese pap...

Adjusting the gap and angle of the blade or disc knife of the Paper Roll Slitting Rewinding Machine is a key step to ensure the quality of slitting and rewinding. He...

The Paper Slitting Rewinding Machine is a mechanical equipment commonly used for processing paper, film and other roll materials. It can cut large rolls of materials...

1. The machine cannot startCheck the power supply: confirm whether the power plug is firmly inserted into the socket and whether the power cord is damaged.Check the ...

GET A QUOTE